We Help Hearables Achieve Their True Potential

Iontra empowers device manufacturers to deliver superior hearable products.

Our cutting-edge technology enables faster charging, extended battery life, and improved battery health. By reducing warranty claims and enhancing product reliability, Iontra helps manufacturers maintain customer satisfaction and boost brand reputation. Our versatile technology is compatible with various hearable device and battery configurations.

Enjoy a faster time to market with minimal design changes using an Iontra-enabled USB-C charging brick.

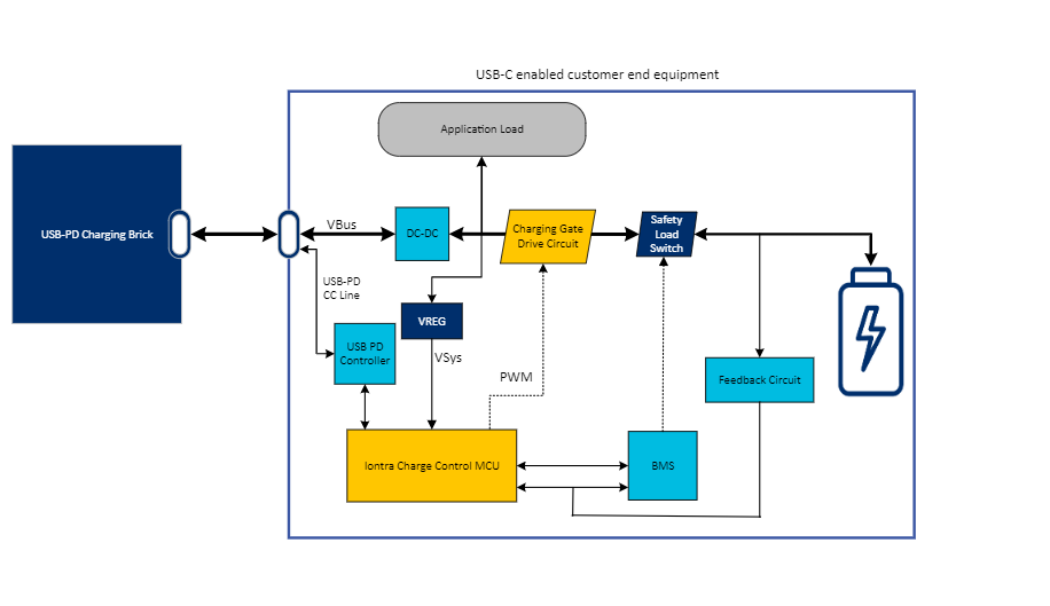

Major Components:

- USB-PD Controller

- The USB-PD controller can be stand alone or integrated into the USB sink side MCU. It does require the ability to pass through or negotiate Iontra Vendor Defined Messages (VDMs) in order to establish an Iontra charge.

- Iontra Charge Control MCU (ICC)

- The ICC MCU is required to run the Iontra charging algorithm, controls the charging circuit, stores battery specific recipe information, and gathers feedback on battery vitals. Depending on your requirements or the MCU chosen, the ICC MCU can also accommodate your application’s functionality. The ICC MCU has certain requirements in order to be capable of Iontra charging. Iontra’s Iontic MCU covers these needs and allows your functionality in an independent core, while lowering solution cost. For a list of third party MCUs that are Iontra capable, please contact Iontra directly.

- Charging Gate Driver Circuit

- The Charging Gate drive Circuit is directly controlled by the ICC MCU, typically through a precision PWM. Typically this circuit is composed of a gate driver and a discrete 2L Buck design. Iontra can work directly with you for the architecture and design of this circuit to meet both your end equipment’s and Iontra charging needs.

- DC-DC converter

- The DC-DC converter in in your design may need to be modified to accommodate higher peak currents of Iontra Charging method, especially for applications focused on faster charging. This need will be dependent on the DC-DC characteristics, the focus of the Iontra charging method, and the recipe parameters agreed upon.

- Feedback Circuit and BMS

- In order for Iontra Charging to be implemented, the ICC MCU needs feedback on battery voltage, current, temperate, and state of charge. Depending on your current implementation, this can be accomplished with updates from your BMS chip. In most cases, direct feedback is needed to the ICC MCU to accomplish Iontra charging.

Improved performance at any scale.

There has never been more demand for high-performance lithium batteries. And at every scale – from cars and trucks to hearing aids and headphones.

Small Devices

100 mA — 6 A charging current

Portables

3 – 45 A, <27V charging current

E-mobility and Industrial

Up to 400 A, >27V charging current

Custom Applications

Recommended Reading

Press Releases

Iontra Named LG Energy Solution Battery Challenge Winner

Press Releases

Iontra Closes $45 Million Series C

Contact us.

Iontra is poised to change the EV industry with breakthrough charging technology that delivers real benefits to drivers and manufacturers alike. Best of all, it can be implemented faster and more easily than you may realize.

Contact us today for a personal presentation or to request a sample battery recipe and data set.